Quality machines deliver quality products. If the machines are of good quality they deliver great pe...

With over thirty years’ experience in Packaging Industry primary for closures, we are the leader and the perfect partner for the provision of complete aluminum cap manufacturing solutions, tailor-made to suit specific market requirements in Ashgabat. Having a sole provider for the entire production line is a key competitive advantage, and with us, this plus is amplified by the fact that our skills extend well beyond the machines and processes.

Sarswati Enterprises provides machinery and complete plants for the ROPP Caps and closures to be used in Pharma & Liquior sectors – markets in which it is a recognized worldwide leader. Its strength lies in the application of innovative technology, and its commitment to research and development in Ashgabat.

we are provided world best industry services in here so you can trust on us for grow industry

With modern process and control technology, it helps to automate, optimise and validate your production sequences.

Production costs refer to all of the direct and indirect costs businesses face from manufacturing a product or providing a service.

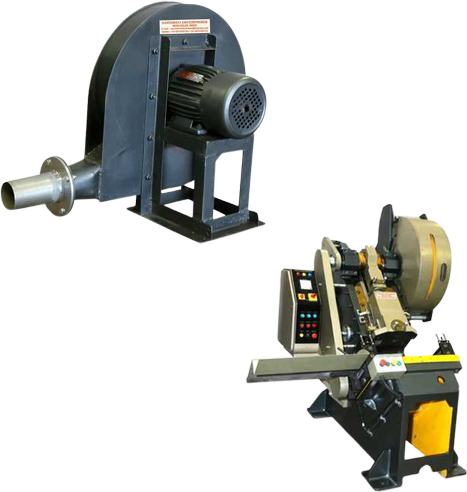

To get the most out of your machine, it is important to use the right parts, understand how the machine works, and carry out preventive and predictive maintenance.

our personnel are your most valuable resource, and the safety of their working environment must always come first. Our long-lasting parts and maintenance tools are carefully designed with one thing in mind – to ensure stable and safe operation.

From installation to eventual replacement, you will receive the optimum performance out of each part, giving you increased uptime, higher reliability, lower maintenance costs, and better personnel protection.

Aluminium Roll-on Pilfer Proof caps that can be made in plain, printed and embossed designs with different caps diameter. The color and text to be printed on the bottle can be customized as per client’s specification.

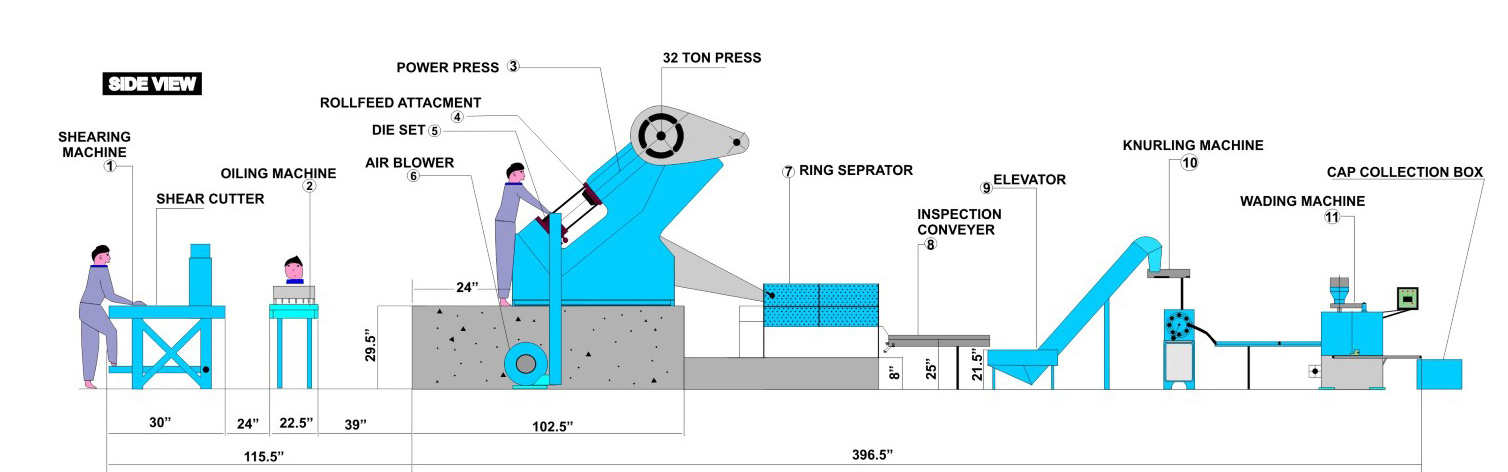

The entire process is with minimal human intervention and requirement.

Aluminium sheets are coated and printed in-house or from outside and then cut into strips for further fabrication.

These sheets are then punched on automatic power presses.

Through the use of various conveyors and hoppers these caps are sent to knurling machine to perform knurling, beading & perforation operations.

From the knurling machine the caps are sent to wadding machines tofix the wads inside the caps.

Get in touch with Sarswati Enterprises - trusted ROPP Caps machinery plants setup

Quality machines deliver quality products. If the machines are of good quality they deliver great pe...

Quality machines deliver great output. The modern and innovative machines not only produce perfect p...

When it comes to performance, quality of the machinery is the most. Good quality machines not only g...