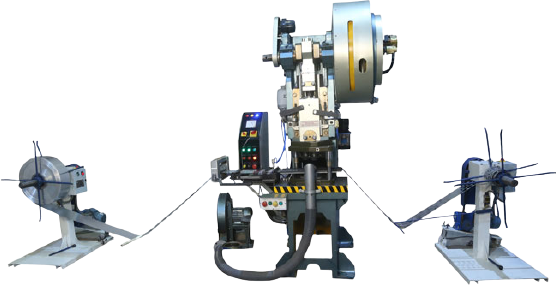

Aluminum Seal Machinery with Decoiler & Rewinder is an automatic machinery for production of various sizes of aluminum seals as per the requirement of the customer. Decoiler feeds the aluminum roll towards the Power Press where the aluminum is punched and later on the scrap roll is moved towards rewinder. All this is done automatically without any human intervention.

Press is equipped with centralized and automatic lubrication system to all important points in the machine. Whole body is made of resistant steel. Properly sized components are sturdily connected with accurate weld to ensure a rigid structure. All parts are specifically machined on precision machines for perfect alignment of guiding surfaces and ensure long tooling life.

Specifications & Dimension are below:

| Specification | Dimension |

| Tonnage | 32 Tons |

| Ram Adjustment Slides | 5 mm |

| Fix Stroke |

100 mm |

| Bed Width |

500 x 630 mm |

| Wheel Size |

700 mm |

| Motor |

2 HP |

| Hole in Ram |

40 x 70 mm |

| No. of strokes per minute | 110 to 120 |

| Fixed inclination | 90 degrees (Straight) |

| Floor Area | 1350mm 2200mm x 2200mm (Approx) |

| Weight |

1800 kg (Approx) |